Promerus’ PDM-5013 material is designed for redistribution layers in next generation technologies.

Features

Overview

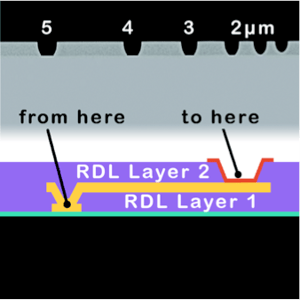

Redistribution is a process that utilizes photopatternable dielectrics to relocate electrically conductive traces.

In an industry moving toward smaller features and lower cure temperatures (170-200C), polynorbornenes are finding their advantage in today’s advanced packaging technologies. Polynorbornenes have an inherently high glass transition temperature (Tg) from their rigid polycyclic olefin backbone.

Unlike its competition, PDM-5013 does not need a high cure temperature to increase the Tg. Instead its low cure temperature, balance of strength and elongation, make it an attractive candidate for next generation packaging technologies.

Properties

| Property | Positive Tone | Negative tone |

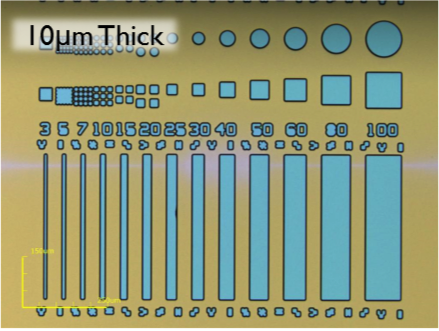

| Film Thickness | 6 - 10 | 6 - 10 |

| Dose (mJ/cm2) | 350 - 600 | 400 - 700 |

| Via Resolution (µm) | 3 - 7 | 5 - 7 |

| Cure Condition (ᵒC/hrs) | 220/2 | 170/1 |

| FT loss during cure (%) | < 10 | < 10 |

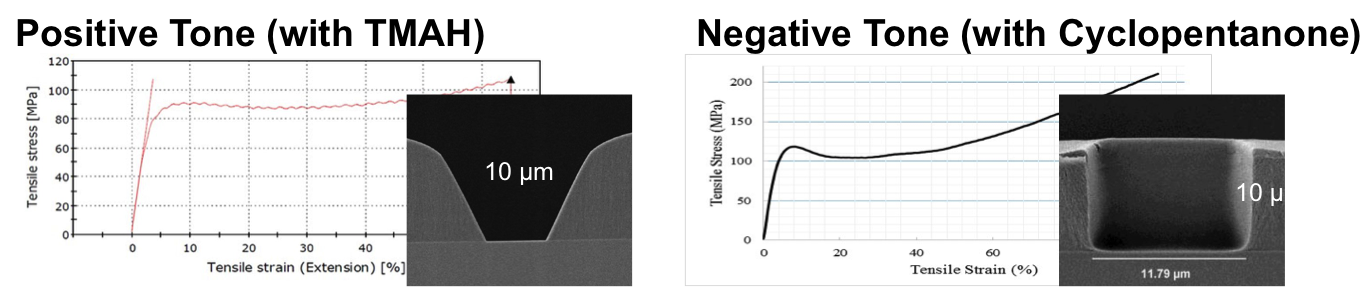

| Taper Angle (deg) | 60 - 65 | 90 |

| ETB (%) | 41 | 91 |

| Tensile Strength (MPa) | 90 | 161 |

| Tg(ᵒC) | 233 | 180 - 210 |

| Td5 (ᵒC) | > 300 | 270 - 280 |

| CTE (ppm/K) | 60 - 65 | 60 - 65 |

Promerus is a technology-driven organization providing advanced material solutions for the next generation of applications. These materials are based on high-purity cyclic olefin polymers that provide outstanding electrical, mechanical, optical and thermal properties. For more information, fill out the form below to explore our full list of materials and applications.

Download the full materials guide to uncover the appropriate materials for your application.

This free guide to Promerus’ materials and applications is designed to help you better understand your options when it comes to polymer application requirements. Additionally, the guide will help you:

Ready to take the next step? Fill out the form below.