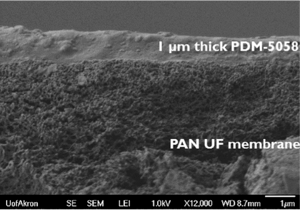

Promerus’ PDM-5058 thin film pervaporation membrane requires less energy than traditional distillation.

Features

Overview

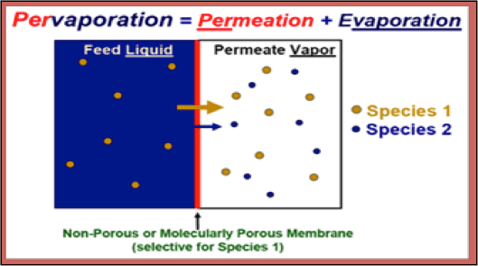

Pervaporation is a process in which molecules are separated through a membrane under the aid of vacuum. This process requires less energy than traditional distillation and is actively being sought out by the biofuel industry for advanced separation and purification of fermentation broths.

PDM-5058 is based on cyclic olefin polymers (COP). Their molecular cage structure inherently allows for separation at the molecular level, while maintaining high flux across the membrane.

Properties

| Feed Chemical | Separation Factor | Flux (g/m²/hour) for 10 micron thick membrane | Feed Concentration |

| n-Butanol | 70 | 1200 | 5% |

| Isobutanol | 35 | 1070 | 5% |

| Propanol | 9.7 | 470 | 5% |

|

Ethanol |

5.4 | 250 | 5% |

|

Ethanol |

3.4 | 440 | 10% |

| Ethyl Acetate | 90 | 1780 | 5% |

| Methyl Ethyl Ketone | 51 | 1960 | 5% |

| Tetrahydrofuran | 48 | 940 | 5% |

Promerus is a technology-driven organization providing advanced material solutions for the next generation of applications. These materials are based on high-purity cyclic olefin polymers that provide outstanding electrical, mechanical, optical and thermal properties. For more information, fill out the form below to explore our full list of materials and applications

Download the full materials guide to uncover the appropriate materials for your application.

This free guide to Promerus’ materials and applications is designed to help you better understand your options when it comes to polymer application requirements. Additionally, the guide will help you:

Ready to take the next step? Fill out the form below.