Promerus’s PDM-5001 Adhesive Paste is a thixotropically-controlled material solution that prevents stiction of MEMS devices.

Overview

PDM-5001 is designed for use as a dispensable coating that serves as an adhesive. It’s thixotropic and is typically dispensed through a syringe into a cavity.

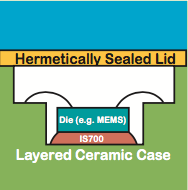

A MEMS device (microelectromechanical system) can be placed onto the PDM-5001 adhesive, and then the adhesive is cured. After this process, the package can be hermetically sealed. PDM-5001 produces no residue at temperatures up to 330 ̊C—thus preventing stiction of MEMS devices.

Its main use is in die attach (also known as die bonding), which is the process of attaching a die to flexible circuits and circuit boards. PDM-5001 can also be dispensed onto flexible circuits and circuit boards.

Paste Properties

| Viscosity (25 ̊C) | 15,000 – 50,000 cPs |

| Solvent | NMP |

| Bake Conditions |

120 ̊C for 30 minutes; 330 ̊C for 30 minutes |

Film Properties

| Moisture Absorption | 1.0% |

| Glass Transition Temperature (Tg) | 165 ̊C |

|

Ionic Impurities (Na+, NH4+, K+, HCOO-, Cl- ) |

Less than 5 ppm |

| Coefficient of Thermal Expansion | 90 ppm/ ̊C |

|

Thermal Decomposition Temperature (5% weight loss) |

510 ̊C |

| Tensile Strength | 115 MPa |

| Elongation (Break Point) | 4% |

| Tensile Modulus | 3.2 GPa |

Promerus is a technology-driven organization providing advanced material solutions for the next generation of applications. These materials are based on high-purity cyclic olefin polymers that provide outstanding electrical, mechanical, optical and thermal properties. For more information, fill out the form below to explore our full list of materials and applications.

Download the full materials guide to uncover the appropriate materials for your application.

This free guide to Promerus’ materials and applications is designed to help you better understand your options when it comes to polymer application requirements. Additionally, the guide will help you:

Ready to take the next step? Fill out the form below.